Academics / Courses / Course DescriptionsMECH_ENG 340-3: Computer Integrated Manufacturing III: Manufacturing Automation

VIEW ALL COURSE TIMES AND SESSIONS

Prerequisites

ME 340-2 or consent of instructor.Description

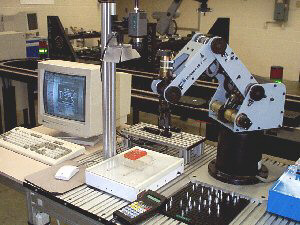

Use of computers to improve productivity and reduce cost in manufacture of discrete parts and assemblies. Manufacturing automation: sensors, actuators, and computers for automation; principles of computer control; programmable logic controllers; robotic devices; assembly automation.

Use of computers to improve productivity and reduce cost in manufacture of discrete parts and assemblies. Manufacturing automation: sensors, actuators, and computers for automation; principles of computer control; programmable logic controllers; robotic devices; assembly automation.

Who Takes It

The course is aimed at advanced undergraduate and first year graduate students who are interested in the most frequently used technologies and methods for automating manufacturing and assembly operations. ME, MfE, IE, and EE students have generally taken this course.

What It's About

The course offers a blend of practical skills and a basic understanding necessary for an engineer to be able to address an array of automation tasks such as process/machine monitoring, execution of controlled motions, programming and integration of sequential controllers and robotic devices into complex systems, etc. The course is structured around weekly lectures that introduce the theoretical basis and extensive weekly laboratory exercises in which students, in a hands-on environment, learn the pragmatic implementation skills.

Upon completion of ME 340-3 students should be able to:

- Select and implement digital/analog sensors and actuators for different assembly and manufacturing tasks in conjunction with real-time control computers.

- Develop program code for real-time control/monitoring applications.

- Design and implement simple stepping - or DC-motor based motion control systems.

- Analyze and program articulated robotic devices.

- Use computer vision systems.

- Design, program, and implement sequential logic control tasks using PLCs.

- Perform system integration to solve complex assembly tasks.

Minisyllabus

- Computers for automation - Interfacing to external devices

- Sensors and actuators - Analog and digital devices

- Motion Control - Introduction to computer control

- Sequential Control - Programmable Logic Controllers (PLCs)

- Robot programming

- Fundamentals of machine vision

- Automated assembly

Labs

- Binary Devices and I/O

- Analog Devices and I/O

- Motion Control

- Manufacturing System Simulation

- Robot Programming

- Computer Vision

- PLC Programming

- Automated Assembly

Assessment/Evaluation

In general, performance evaluation will be based on weekly problem sets, laboratory participation and reports, a midterm and a final exam. All exams will be open book and open notes. However, keep in mind, assessment strategies do vary by instructor.

Textbook

Handouts

Reference Material

Systems Approach to Computer Integrated Design and Manufacturing, N. Singh, John Wiley and Sons, Inc., 1996.